Zinc Whiskers Information

Zinc Whiskers represent a special situation that requires very careful and extensive effort to successfully neutralize. Data Clean has been helping its customers deal with the threat of Zinc Whiskers for many years.

Zinc Whiskers

![]() Zinc Whiskers - What You Should Know Now! (2009)

Zinc Whiskers - What You Should Know Now! (2009)

By

Rich Hill

![]() Are Zinc Whiskers Growing in Your Computer Room?

Are Zinc Whiskers Growing in Your Computer Room?

By

Rich Hill

![]() Zinc

Whisker Contamination - A Paper on the Effect and Abatement of

Zinc

Whisker Contamination - A Paper on the Effect and Abatement of

Zinc Whiskers in Data Processing

Centers

By

David Loman, HP Services

ARE ZINC WHISKERS GROWING IN YOUR COMPUTER ROOM?

- Are you having unexplained hardware failures – particularly disk drives and power supplies?

- Are you having unexplained data corruption problems?

- Do your problems get more frequent or severe after you move equipment or work in the underfloor?

- Have you installed the latest lightning fast server or CPU only to find it doesn’t seem as reliable as your old legacy system?

If you answered Yes to any of the foregoing questions, you might have Zinc Whiskers. If you think zinc whiskers are what happen when the tin man forgets to shave – guess again. Zinc whiskers are real and they could be growing right inside your computer room! Read on to learn what zinc whiskers are, where they come from, and what you can do about them.

WHAT ARE ZINC WHISKERS?

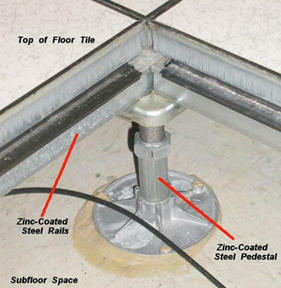

Zinc whiskers are a phenomenon that can occur on the bare metal surfaces of access flooring systems. Affected components include some wood-core and some concrete-core computer room flooring panels as well as some pedestals and stringers. The whiskers grow on the underside (plenum side) of the floor panels or the exposed surfaces of the structural components.

Zinc whiskers are a phenomenon that can occur on the bare metal surfaces of access flooring systems. Affected components include some wood-core and some concrete-core computer room flooring panels as well as some pedestals and stringers. The whiskers grow on the underside (plenum side) of the floor panels or the exposed surfaces of the structural components.

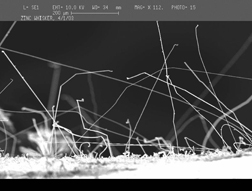

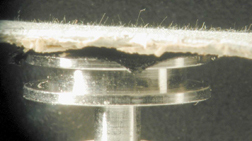

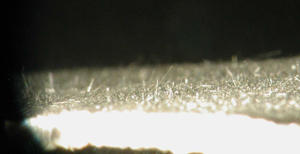

The whiskers are typically 2 microns in diameter and over time, (many years) the whiskers can grow to be several millimeters in length. While the whiskers are attached to the floor panel or pedestal, they are basically benign. When the whiskers break free however, they become airborne and can circulate freely throughout the facility and get blown into your equipment.

WHAT HAPPENS?

You should remember that zinc is a metal and a good conductor of electricity. If a whisker comes to rest on an exposed circuit card inside your equipment, it could cause a short; most likely an intermittent short. And as you know, an intermittent problem is the most difficult to detect and fix. Symptoms of Zinc Whisker related failures range from minor data corruption or anomalies to catastrophic hardware failures. A commonly reported problem is a high incidence of power supply failures. You may also experience problems with your tapes and drives. Many victims of zinc whisker problems seem to experience an increase in problems when they migrate to new systems.

You should remember that zinc is a metal and a good conductor of electricity. If a whisker comes to rest on an exposed circuit card inside your equipment, it could cause a short; most likely an intermittent short. And as you know, an intermittent problem is the most difficult to detect and fix. Symptoms of Zinc Whisker related failures range from minor data corruption or anomalies to catastrophic hardware failures. A commonly reported problem is a high incidence of power supply failures. You may also experience problems with your tapes and drives. Many victims of zinc whisker problems seem to experience an increase in problems when they migrate to new systems.

Zinc Whiskers are so small that the normal dust filters used on computer equipment are ineffective. If you want to stop zinc whiskers from entering your equipment you need HEPA filtration.

If you haven’t heard about zinc whiskers before, you may be skeptical - It’s easy to ignore a condition that is under the floor and barely visible at that. But the science behind zinc whiskers isn’t a great mystery, nor is it really new. (Bell Labs reported on metal whiskering in the telecommunications industry back in the 1940s. Telecom and computer companies are still dealing with whiskering from various metal sources today.) Ferrous metals such as steel are normally plated to prevent surface corrosion. Zinc is a very common plating material since it is fairly corrosion resistant, produces a good aesthetic appearance, and is reasonably inexpensive.

If you haven’t heard about zinc whiskers before, you may be skeptical - It’s easy to ignore a condition that is under the floor and barely visible at that. But the science behind zinc whiskers isn’t a great mystery, nor is it really new. (Bell Labs reported on metal whiskering in the telecommunications industry back in the 1940s. Telecom and computer companies are still dealing with whiskering from various metal sources today.) Ferrous metals such as steel are normally plated to prevent surface corrosion. Zinc is a very common plating material since it is fairly corrosion resistant, produces a good aesthetic appearance, and is reasonably inexpensive.

A normal bi-product of the plating process is high molecular level stresses in the plated metal. The crystalline structure within the metal will attempt to relieve the internal stress by enlarging the structure through the growth of crystals. The growth path is outward and the material is literally pushed out of the surface of the metal. These crystalline growths are known as whiskers. In the case of access flooring, the zinc electro-passivation coating on the steel sheet used to form the bottom pan of certain wood-core and concrete-core panels can have just the right makeup of zinc to promote whiskering of the zinc finish. The same is true for certain pedestals and stringers used to support the floor.

Because whiskering happens at the molecular level, the specific molecular make-up of the metal finish can literally prevent or exacerbate the problem. Moreover, the problem is not affected by environmental conditions such as temperature and humidity. If your panels are destined to grow whiskers, they will grow regardless of the environmental conditions.

WHY NOW?

Two things are happening in computer rooms to cause zinc whiskers to be noticed now. One, the floors are now old enough in many facilities. The floors have simply been in place long enough to grow reasonably sized whiskers and enough have broken off the panels, floated around and landed inside equipment. Your floor may have been growing whiskers for years without you knowing about it because they weren’t that large.

Two things are happening in computer rooms to cause zinc whiskers to be noticed now. One, the floors are now old enough in many facilities. The floors have simply been in place long enough to grow reasonably sized whiskers and enough have broken off the panels, floated around and landed inside equipment. Your floor may have been growing whiskers for years without you knowing about it because they weren’t that large.

Second, is the continually shrinking size of electronic assemblies. The lead pitch (lead to lead spacing) on integrated circuits and other components has shrunk dramatically. A whisker has a much better chance of causing a short on today’s electronics versus 1980s vintage equipment. Even a small whisker has a chance of shorting two leads.

The same issue is true for tapes. The bit density continues to increase and therefore contamination can more easily obliterate a large portion of data.

On the human side, zinc whiskers are not known to cause any threat to people. Although research on exposure limits has not been published, overexposure is not thought to be a factor since indoor concentrations are relatively low. Individual whiskers themselves are not toxic like lead or asbestos. Like many minerals, low levels of zinc are useful to humans while higher concentrations can be dangerous; zinc is actually necessary in our bodies and is contained in most mineral supplements.

ARE YOU AT RISK?

First, determine if you are at risk. If you don’t have wood-core access panels or flat-bottomed concrete-core access panels, you don’t need to worry about your raised floor panels giving you zinc whisker problems. However, if you still suspect zinc whiskers, you should check out your pedestals and stringers.

First, determine if you are at risk. If you don’t have wood-core access panels or flat-bottomed concrete-core access panels, you don’t need to worry about your raised floor panels giving you zinc whisker problems. However, if you still suspect zinc whiskers, you should check out your pedestals and stringers.

Follow these steps to determine if you are at risk:

- Look at the bottom of the panel. If it has dimples or cutouts – not flat – you’re panels are not at risk, go to Step 3. If it is smooth and flat, you are at risk. You can confirm that the panel is wood-core or concrete-core by looking at a cut tile along the perimeter or at a cable cutout. Looking at the cut edge, you should see the core – particleboard for wood or gray concrete, go to Step 2.

- Now, look carefully at the appearance of the exposed metal on the bottom of the panels. Are your panels uniformly gray with a dull to slightly shiny finish? If so, you are at risk. These panels have a uniformly gray color with a dull to slightly shiny finish. Zinc plating can also be applied using Hot Dipped Galvanization (HDG). This process yields a bright mottled finish like on a metal washtub. HDG plating typically does not grow whiskers.

Note: The incidence of zinc whiskers on concrete-core panels is low because relatively few flat-bottomed concrete-core panels were manufactured.

- While you are checking the appearance of your floor panels, check your pedestals and stringers as well. Using the appearance definitions above, your pedestals and stringers may also be at risk. Note that most aluminum pedestals will appear uniformly dull gray but these are not at risk. Only components manufactured from ferrous metals (a magnet will stick to them) are potential sources.

Before purchasing, it is recommended that you consult

with a Data Clean Representative for professional guidance.

DO YOU HAVE ZINC WHISKERS?

If your floor panels are at risk or you think your pedestals or stringers might be at risk, you need to check for whiskers. The simplest and most straightforward method of detection is good old visual inspection. Rest the tile on its edge and sight down the plane of the tile and view the bottom pan with a flashlight. Whiskers will appear as small shiny or glittering protrusions from the metal. (A darkened room helps) Remember, whiskers are typically only 1-10mm in length. You should review several panels to get a good perspective of your situation.

Be Careful! This is the time to exercise caution! Zinc whiskers break off the panels easily. Sliding, or scuffing the panels will cause them to break off. Rubbing your hand over the panel will cause them to break off!

If you see whiskers, you now have proof. However, if you don’t see whiskers, you can’t automatically assume you are safe. You may not have checked the right panels, or the whiskers may not have grown enough to see.

The most common method for confirming zinc whisker contamination is to utilize Scanning Electron Microscopy (SEM) to review field samples. Samples can be collected not only from the floor panels and understructure components but also from the surface of specific components, such as a failed power supply. SEM testing is essential in confirming the need for a remediation program.

A less expensive but somewhat less useful testing method is wipe sampling of surfaces. With wipe sampling, a wet wipe is used to wipe a small, defined area in the room. (If zinc whiskers are inside your equipment, they are also everywhere else in your computer room.) The wipe is sealed in a plastic bag and sent to an environmental lab. The lab will then test for the presence of zinc on the wipe. The laboratory analysis typically costs less than $20 per sample with a 3-5 day turnaround. The lab won’t be able to see individual zinc whiskers but they will be able to give you the concentration of zinc in the sample. If your wipe tests turn out positive, it’s not conclusive (the zinc could be from a different source) but it’s a good bet you’ve got whiskers!

GETTING RID OF WHISKERS

If you determine you have a zinc whisker problem, the big question is what to do about them. In the short term you can and should do nothing! Literally nothing. If the whiskers are undisturbed, they will generally remain attached to the panels. However, this means that you can’t move the panels to facilitate equipment moves and rearrangements or even repairs. This is not a reasonable solution for most facilities.

In the long term, you don’t have any option other than to replace the affected floor panels. The panels can be cleaned but the whiskers will grow back! You could seal or paint the bottoms of the panels but research has shown whiskers will grow right through most coatings. Moreover, the cost of painting would most likely exceed the cost of replacement panels.

Replacement is no simple task either. The more zinc related equipment problems you’ve had, the more careful you need to be. You first need to determine the extent of your problem. Inspect a number of panels (at least 20) to decide of you need to replace all your panels or just a few. The more you replace the bigger the potential impact of the project. Zinc Whisker remediation is a big deal and should only be undertaken after careful planning. Without proper equipment, personnel and procedures, the likelihood of success is low. The following outlines the general procedure for panel replacement.

Step 1. – Power down and REMOVE from the environment any and all equipment that you can. If the whole room can be shut down, do it!

Step 2. – Power down as many air conditioning units as you can for the remaining load.

Step 3. – Protect remaining equipment with plastic barrier tents. Create safe envelopes for equipment by sealing plastic sheeting between the ceiling and the floor. If you still have airflow under the floor, you will need to create underfloor barriers as well. This step is critical since these barriers will protect your equipment from zinc-laden airflow during the replacement process. Note: This step is often difficult to perform because of the physical layout of the room. If this step cannot be performed, compensating changes to the work plan must be implemented.

Step 4. – Remove affected panels by carefully lifting (without sliding or jostling them) and placing them in a plastic bag. Place only one panel in a bag and fold and seal the bag. Remove the panel from the room. Don’t reuse the bags!

Step 5 – Clean the underfloor plenum, flooring understructure, and underfloor infrastructure using HEPA vacuums and wet wiping.

Step 6 – Clean the underside of unmovable panels (under equipment that cannot be moved) using wet wiping.

Step 7 – Install replacement panel

Step 8 – Repeat Steps 4 – 7 throughout remainder of affected area.

Step 9 – Clean the entire room and its contents. Zinc Whisker contamination does not remain in the underfloor plenum. The whiskers can and do end up on the walls, ceiling, and all items within the room.

Step 10 – Carefully remove barriers, reinstall equipment.

Remember to map or mark panels that were not removed, if any. These panels should be monitored for continued whisker growth and replaced coincident with future equipment moves.

Zinc Whiskers are Manageable

Zinc whiskers are real but manageable. Many companies have successfully dealt with the problem and no doubt many more will be forced to deal with it in the coming years. Be proactive! Even if you haven’t had problems, check your panels. If you think there may be zinc whiskers in your future, get some money in your budget to replace the floor before you have a problem.

Data Clean provides consulting and remediation services for Zinc Whiskers and other contamination problems. Ask your local Data Clean representative for more information.

** Photos provided courtesy of NASA.